The best stereo microscope pairs simple controls and precise optical alignment for smooth switching between magnifications. distortion is minimized and depth perception is enhanced with quality glass lenses. a sturdy frame and vibration-dampening base contribute to stable imaging, even under extensive use. The best stereo microscope features integral LED illumination with adjustable intensity for precise light control, providing crisp and clear viewing of biological or material samples for research and educational studies.

The best stereo microscope is critical to science and manufacturing advancement. In the medical research arena, the best stereo microscope aids microscopic blood and tissue testing for accurate diagnostics. Research institutions use the best stereo microscope in cell culture analysis, detecting bacterial growth, and research on biofilms. Industrial laboratory environments utilize the best stereo microscope for product quality assurance and surface finishes evaluation. The best stereo microscope is also applied in environmental science to support monitoring of plankton populations and particles of pollutants, to enhance ecological studies and sustainability science.

In the short term, the best stereo microscope will be a networked and completely digital platform. Integration with AI-powered recognition systems will make automated cell, material, and organism recognition possible. Cloud storage will allow easier information sharing and archiving. The best stereo microscope is set to embrace holographic and super-resolution techniques, allowing researchers to see structures at the molecular scale. This technology will open new fields in diagnostics, nanoscience, and education, which will expand the use of microscopic observation across industries.

A well-maintained best stereo microscope gives reliable performance and long operating life. Check optical elements regularly for dust, fingerprint, or oil residue. Use only authorized manufacturer cleaning materials to prevent lens coating damage. Store the best stereo microscope upright, supported, and covered when not in use. Check focusing mechanisms for smooth operation and illumination system for uniform brightness. Standard maintenance procedures minimize downtime and preserve imaging quality for education and research.

A best stereo microscope is an entry to the micro world, bringing one into contact with structures that characterize life and matter. It works by magnifying specimens through accuracy lenses and management of light, producing good images for research and study. The best stereo microscope gives assistance to microbiology, pathology, and materials engineering and other fields of study, enabling close examination and data collection. With features like LED illumination and picture software, it adds more precision, stability, and efficacy to users everywhere.

Q: What is a microscope used for? A: A microscope is used to magnify tiny objects or structures, allowing detailed observation of cells, microorganisms, and materials that are invisible to the naked eye. Q: How often should a microscope be calibrated? A: To maintain measurement accuracy and ensure accurate focus during research or analysis, regular calibration should be performed, typically once or twice a year. Q: What type of light source is commonly used in a microscope? A: Most modern microscopes use LED or halogen light sources, which provide stable light and adjustable brightness for clear images at a wide range of magnifications. Q: Can a microscope be connected to a computer? A: Yes, many microscope models feature USB or HDMI ports that allow image capture and digital display through specialized imaging software. Q: How should a microscope be stored when not in use? A: A microscope should be covered with a dust shield and stored in a cool, dry location to prevent contamination and protect optical components from humidity.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

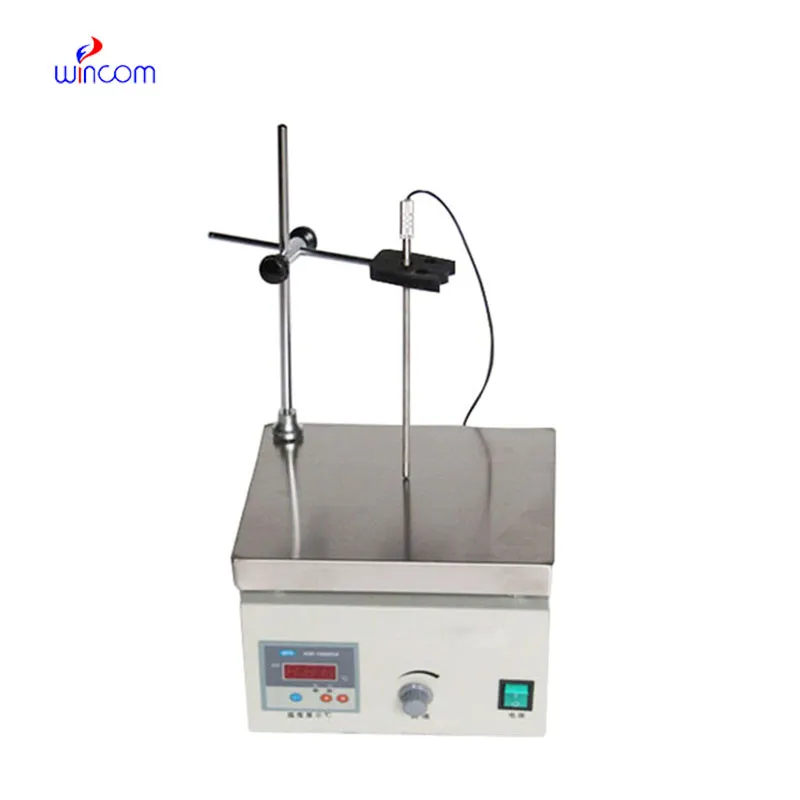

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

Could you please provide more information about your microscope range? I’d like to know the magnif...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China